Lubrication System Solutions

Centralized Lubrication Solution for Wind Power

Application Environment

China's large wind turbines usually have the tower height ranging from 50 meters to 160 meters, and the blade length from 30 meters to 90 meters. Wind power plants are primarily located in remote areas such as valley, wilderness, the gobi desert, offshore areas where aboundant wind energy resources exist. Due to the costly price of wind turbines, harsh working environment, and awesome tower height, the maintenance of wind turbines is very inconvenient. Therefore, in order to ensure the reliable and stable long-term operation of wind turbines, wind turbine manufacturers put forward extremely strict requirements for lubrication systems which need to provide continuous lubrication to relevant lubrication points of the wind turbine regularly and quantitatively. The manual method of filling lubricating grease fails to fully satisfy the lubrication demand of wind turbines and is also difficult and risky to implement. Currently, centralized lubrication systems are used worldwide as the major device to provide reliable lubrication for wind turbines.

Solutions

In view of the industry pain points such as the wide dispersion of wind turbines, adverse environment, challenging maintenance, and expensive equipment price, Paguld has specially developed a series of centralized lubrication systems for large wind turbines, which can regularly and quantitatively lubricate each bearing, tooth surface and other parts of the wind turbine, achieveing automatic, multi-point precise lubrication, so that key components in the nacelle and hub are able to achive their best performance. Meanwhile, Paguld lubrication systems can avoid problems such as low injection precision, uneven distribution of grease, and high operation risk in extreme environments caused by manual grease filling, thus reducing operation and maintenance costs of wind power equipment and meeting operators' requirements for higher power generation efficiency.

Application range:

Generator bearing, main bearing, yaw bearing and gear, pitch bearing and gear, etc.

Advantages

Timed, fixed-point, quantitative and orderly grease lubrication

Avoids omissions of lubrication points caused by manual lubrication

Accurate lubrication cycles, precise dosing of grease, grease-saving, eco-friendly

High system pressure, compatible with wide grease range

Compact structure, excellent performance, easy installation and maintenance

Effective lubrication extends WT components’service life and reduce maintenance costs

Features fault alarm function, monitors the lubrication system throughout its operation

Saves lubricant, protects the environment

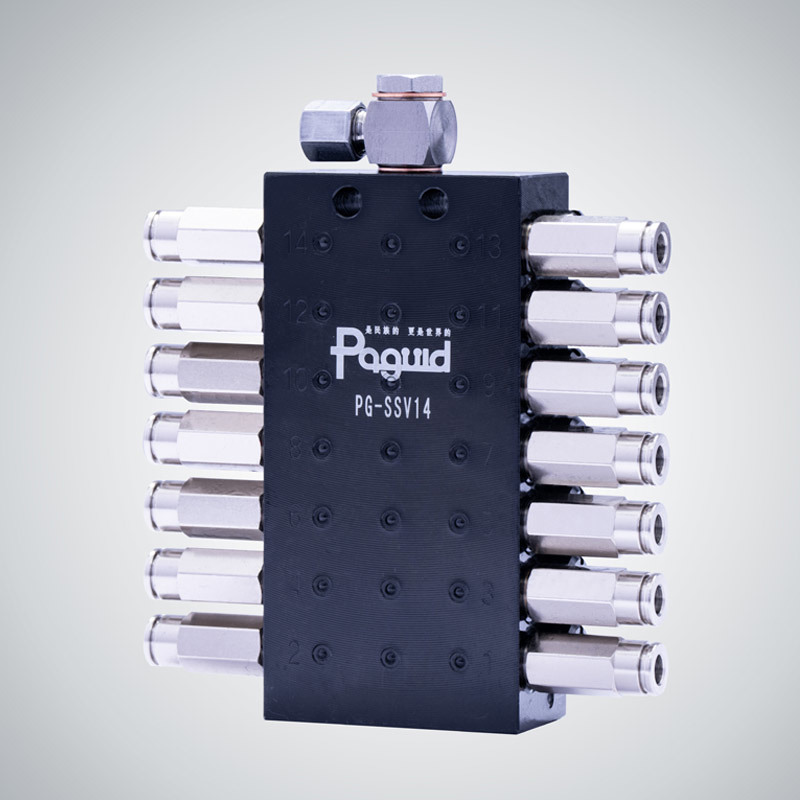

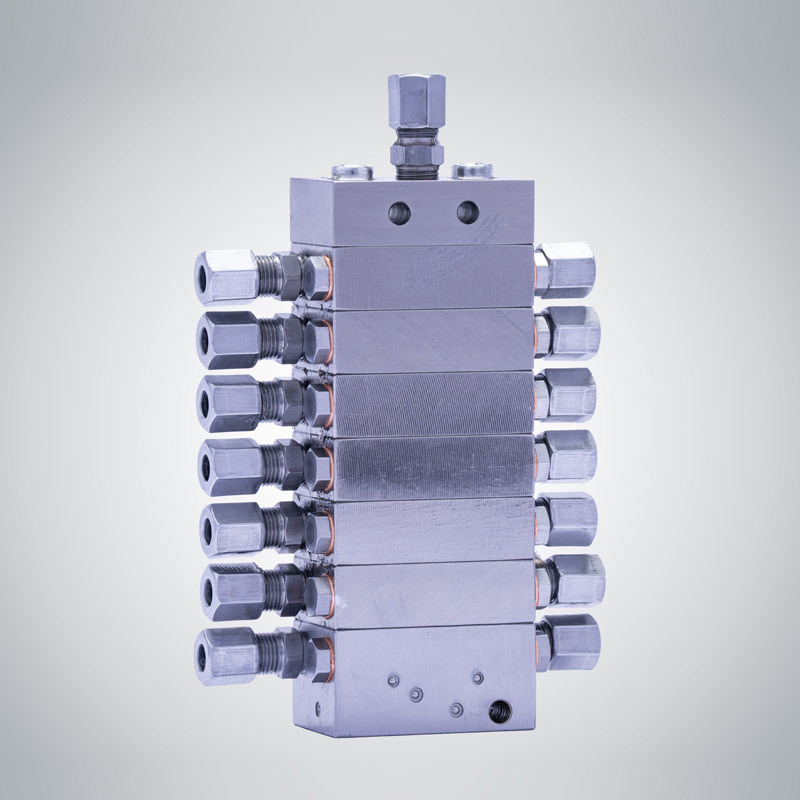

Products

Technical Support

Paguld provides an all-round package of centralized lubrication system technical support for wind turbines, aiming to ensure the power units’ stable operation of the unit and efficient power generation. Paguld 's technical team has profound professional knowledge and rich practical experience, which help them deeply understand the specific needs of customers and provide customers with personalized technical support solutions.

Paguld Technical Support Services is customer-centered, which means we can also provide device installation, debugging and maintenance services, remote fault diagnosis and early warning services, and system transformation, optimization and upgrade services based on different needs. Paguld always put customer’s needs on priority and values their feedback, and is dedicated to providing customers with as best services as they can to ensure the stable operation and efficient power generation of wind turbines.

Customized Services

Paguld is committed to providing customized centralized lubrication systems for wind turbines to cater to different unit models and working environments. Through in-depth analysis of the lubrication requirements and operating characteristics of wind turbines, combined with advanced lubrication technology and design concepts, we customize efficient and reliable centralized lubrication systems for customers, which guarantees all components of the wind turbine are fully and evenly lubricated during operation, effectively reducing wear and failure rate, thus improving the service life and power generation efficiency of the wind turbine.