Proportional directional valve

Category:

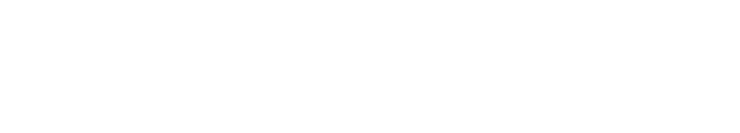

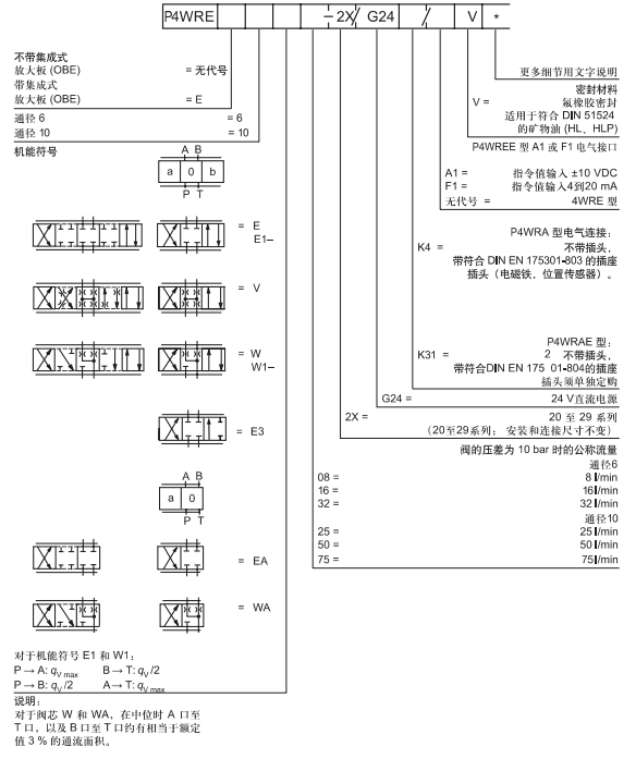

Directly controlled proportional directional valve with displacement electrical feedback and integrated amplification board (OBE) (for model P4WREE); Closed loop control of flow direction and magnitude; The control of the valve is achieved through a proportional electromagnet with a central thread, and the coil can be disassembled separately; For bottom plate installation: The installation surface shall be ordered separately according to ISO 4401 bottom plate; The control valve spool is centered by a spring; Electric controller P4WREE; Integrated amplifier board (OBE) with voltage input or current input (A1 resp. F1); P4WRE (three digit four-way model), separately ordered: digital or analog amplifier, European card standard; Modular analog amplifier; P4WRE... A (two-way four digit model), ordered separately: modular analog amplifier.

400-0532-090

sales@paguld.com

产品介绍

Product Overview

Product Overview

The two position four-way and three position four-way proportional directional valves are directly controlled and have a plate structure; Operated by a proportional electromagnet with a central thread, the coil can be disassembled separately, and the control of the electromagnet can be achieved through an external amplification board (model 4WRE) or an integrated amplification board (model 4WREE).

Technical Parameter

Technical Parameter

| Technical parameter | ||||

| Summary | ||||

| Path diameter | 6 | 10 | ||

| Installation location | Any, it is recommended to prioritize horizontal installation | |||

| Storage temperature range | ℃ | -20~+80 | ||

| Usage environment | P4WRE | ℃ | -20~+70 | |

| Temperature range | P4WREE | ℃ | -20~+50 | |

| Weight | P4WRE | Kg | 2.2 | 6.3 |

| P4WREE | Kg | 2.4 | 6.5 | |

| Hydraulic (measured at P=100bar, HLP46,=40 ℃± 5 ℃) | ||||

| Maximum work pressure | Oil ports A, B, P | bar | 315 | |

| Oil port T | bar | 210 | ||

| When the nominal flow rate is ∆ p=10 bar | L/min | 8,16,32 | 25,50,75 | |

| Maximum allowable traffic | L/min | 80 | 180 | |

| Oil fluid | Mineral oils (HL, HLP) that comply with DIN51524 standards and other fluids, please consult our company! | |||

| Liquid temperature | ℃ | -20 to+80 (priority is given to+40 to+50) | ||

| Viscosity range | /s | 20 to 380 (preferably 30 to 46) | ||

| The maximum allowable pollution level for viscous oil According to ISO4406 (c) |

Grade 20/18/15 | |||

| Hysteresis loop | % | ≤ 0.1 | ||

| Reverse interval | % | ≤ 0.05 | ||

| Reaction sensitivity | % | ≤ 0.05 | ||

| Zero displacement will depend on the pressure oil Changes in temperature and operating temperature |

%/10K | 0.15 | ||

| %/100bar | 0.1 | |||

| Electrical parameters | ||||

| Path diameter | 6 | 10 | ||

| Voltage type | DC | |||

| Command value signal Model P4WRAE |

Voltage input, A1 " | V | ±10 | |

| Current input, F1 " | mA | 4 bis 20 | ||

| Electromagnetic coil resistance |

At 20 ℃ | Ω | 2.7 | 3.7 |

| Max | Ω | 4.05 | 5.55 | |

| Electricity rate | % | 100 | ||

| Maximum coil temperature | ℃ | 150 | ||

| Electrical connection | P4WRE | Equipped with sockets that comply with DIN EN 175301-803 and ISO 4400 standards | ||

| The plug complies with DIN EN 175301-803 and ISO 4400 | ||||

| P4WREE | Equipped with sockets that comply with DIN EN 175201-804 standard | |||

| The plug complies with DIN EN 175201-804 | ||||

| Valve protection level according to EN 60529 | IP 65 plug installed and locked | |||

Product Specifications

Product Specifications

Keywords:

Online Consultation

Related Products

undefined