Smart and Brave Guardian of Wind Power Generation, full Analysis of Hydraulic Pitch Technology (III)

Release time:

2024-05-31

Abstract

1. Hydraulic PitchElectric pitch

As two common pitch technologies, hydraulic pitch and electric pitch have their own unique advantages and limitations in the field of wind power generation. The following is a detailed comparison of the advantages and disadvantages of these two technologies in order to understand their characteristics more comprehensively.

1. Working principle

Hydraulic pitchVS Electric pitch

Hydraulic pitch:The hydraulic pump is used as the working power source, the hydraulic oil is used as the transmission medium, and the solenoid valve is used as the control unit to realize the blade angle change through the extension and retraction of the piston rod.

Electric pitch: The servo motor is used as the power source, and the blade is driven to rotate by the common meshing rotation of the reducer, the output shaft gear and the inner gear of the blade root slewing support, so as to realize the pitch control adjustment.

2. Advantages

Hydraulic pitchVS Electric pitch

Advantages of hydraulic pitch:

1. The hydraulic drive variable pitch system has fast response, large stiffness, large torque and stable operation;

2. The existence of hydraulic damping can absorb the impact torque on the blade shaft, and play a good damping effect on the blade and the fan itself;

3. The bearing used in the hydraulic pitch system is simpler and the structure is stronger;

4. High pressure and no gear, no backlash frequency response fast accumulator to ensure failure safety;

5. The size of the wheel hub and pitch bearing can be smaller, no need to lubricate the gear, reduce the lubrication point of centralized lubrication;

6. At low temperature, the energy stored in the accumulator is small, and the energy stored in the accumulator is easy to monitor through pressure. The accumulator is used as emergency pitch power, with long service life and quick response in emergency.

Advantages of electric pitching:

1. Low energy consumption;

2. Quiet operation;

There is no risk of hydraulic oil leakage, no environmental pollution problems, and less energy consumption;

4. Transmission structure is simple, pitch synchronization, high accuracy;

5. The stability at low temperature is better.

3. Disadvantages

Hydraulic pitchVS Electric pitch

Disadvantages of hydraulic pitch:

1. The industrial chain is not perfect, the price of hydraulic pitch system is high, and the system is more complex;

2. There are many pipe joints, and there are problems of lax sealing and aging sealing ring, and there may be hydraulic oil leakage;

3. When the hydraulic system fails, repair and maintenance are relatively difficult, and professional personnel are required to operate;

4. The continuous operation of the hydraulic pump consumes a lot of energy, and the system heats up relatively higher, which requires a supporting cooler to dissipate the heat of the system;

5. Fluid rotating components are required, with large pressure loss and high component requirements;

6. Hydraulic oil and filter shall be tested and replaced regularly.

Disadvantages of electric pitch:

1. Battery or super capacitor, the service life is relatively short;

The tooth surface wear of the toothed bearing in the pitch system is a common problem, and the method of reserving the hole position of the reducer and replacing the position gear can deal with this wear to a certain extent. However, when the gears in all positions fail again, re-lifting is required to replace the entire bearing or related components;

3. With the increase of the unit capacity, the motor inertia also increases, so that the dynamic response characteristics of the deterioration, and frequent adjustment of the blade, easy to make the motor due to overheating and damage, components are also easy to burn;

4. When the network is frequently cut off for many times, the backup battery will be exhausted, and the problem of not being able to feather may occur;

5. Large megawatt wind turbines have higher wind energy capture and longer and heavier blades, which leads to frequent braking of the pitch motor to feedback energy, so that the pitch braking resistor needs to withstand greater current and energy consumption when working. Long-term energy consumption will make the brake resistance material more susceptible to aging damage, affecting the operating efficiency and power generation of wind turbines.

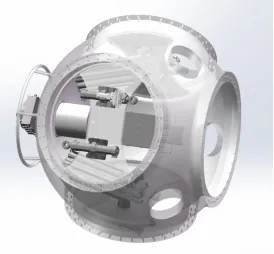

2. Pangu intelligent research and development of hydraulic pitch system

To optimize wind energy conversion efficiency and ease of maintenance,Pangu Intelligent's new solution cancels the traditional hydraulic slip ring design. In this innovative layout, the hydraulic pump station, pitch valve group, accumulator, cylinder and control system are all cleverly integrated and placed in the inner space of the hub.This not only maximizes the use of the limited space inside the hub, but also ensures the coordinated operation and efficient interaction between the various components through precise arrangement and compact structure. Through the motor pump control system, the flow of hydraulic oil can be directly and accurately controlled, and the effect of energy saving can be achieved while achieving precise adjustment of the blade angle; the transmission efficiency is higher and the energy loss is lower.This layout not only improves the overall performance and reliability of the system, but also makes the subsequent maintenance and repair work more convenient and efficient.

The system adopts modular and universal design to realize the universal design of materials among different models. By adopting the assembly mode of standard modules, not only the production process is more flexible and convenient, but also the production efficiency is significantly improved by reducing repetitive work, greatly simplifying the supply chain management, facilitating the maintenance and upgrading of the later period, and significantly shortening the product design cycle,These advantages work together to effectively reduce the manufacturing and operation and maintenance costs of enterprises, and enhance the overall competitiveness.

This scheme has the following advantages:

1.Shorten the line

The hydraulic pump control unit integrates the pump and control system, thereby reducing the pipeline connection from the pump to the control valve and other actuators. This not only simplifies the system structure, but also helps to reduce the fluid resistance and pressure loss in the pipeline.

2.Reduce leakage points

The risk of leakage is reduced due to the reduction of pipe connections. Leakage will not only cause environmental pollution, but may also adversely affect the normal operation of the equipment. Therefore, reducing the leakage point is very important to improve the reliability and stability of the system.

3.Cost reduction

The integrated and modular design of the hydraulic pump control unit helps to reduce the overall cost of the system. This is mainly reflected in reducing the number of pipes, joints and other accessories, as well as simplifying the installation and commissioning process. In addition, due to the reduction in maintenance costs, the overall operating costs will also be reduced.

4.High energy conversion efficiency

Integrated design not only improves the compactness of the system, but also helps to improve the performance and efficiency of the system. Maximize the efficiency of the hydraulic pump, improve energy conversion efficiency, and reduce the cost of driving.

5.Easy to install

Due to the modular and standardized design, the installation process is relatively simple and fast. In addition, due to the reduction of pipe connections and other complex components, errors and problems that may occur during installation will also be reduced.

hydraulic pitch systemThe use of non-gear transmission effectively avoids the problem of traditional gear wear.Significantly improve equipment stability, life, reduce maintenance costs and downtime. The hydraulic pitch system is famous for its high torque and large load capacity, which ensures stable and accurate control of the blades under various conditions and avoids the problem of asynchronous cylinders. It is especially suitable for independent pitch, optimizes fan performance and wind energy utilization, and shows excellent flexibility and performance.

The hydraulic pitch system is developing in the direction of compact structure, low cost and easy maintenance.With technological innovation, hydraulic pitch system will launch more innovative products to meet the diverse needs of the market. the future,Improving the industrial chain and strengthening the intelligent control system will be the two keys to its development.Through the cooperation between the upstream and downstream of the industrial chain, the production efficiency will be improved, the cost will be reduced, and the healthy development of the whole industry will be promoted. At the same time, the optimization of the intelligent control system will further enhance the performance and reliability of the hydraulic pitch system, making it better adapt to the development trend of the wind power field. In short, the hydraulic pitch system will play an increasingly important role in the field of wind power generation with its unique advantages and broad prospects.

Recommended Reading

Paguld Breaks Ground in Thailand – Key Step in Global Expansion

2025-12-16

2025-12-15