Smart and Brave Guardian of Wind Power Generation, full Analysis of Hydraulic Pitch Technology (I)

Release time:

2024-05-27

Abstract

1. The concept, composition and function of hydraulic pitch

As one of the core parts of large wind turbine control system, the technology is to adjust the angle between the blade and the wind direction automatically according to the size of the wind speed by adjusting the pitch angle of the blade, and then control the aerodynamic torque and aerodynamic power captured by the wind wheel to optimize the capture efficiency of wind energy and the operating performance of the generator set. The pitch system is to realize the rotation of the blades, change the pitch angle, and ensure the power balance of the wind turbine above the rated wind speed. In extreme cases, the pitch system will automatically complete the pitch closing action to reduce the resistance of the blades to the wind, thereby reducing the wind turbine Speed and load. This can effectively prevent the wind turbine from being damaged in extreme cases and protect the safety of the wind turbine. The pitch system plays a very important role in the safe, stable and efficient operation of the unit.

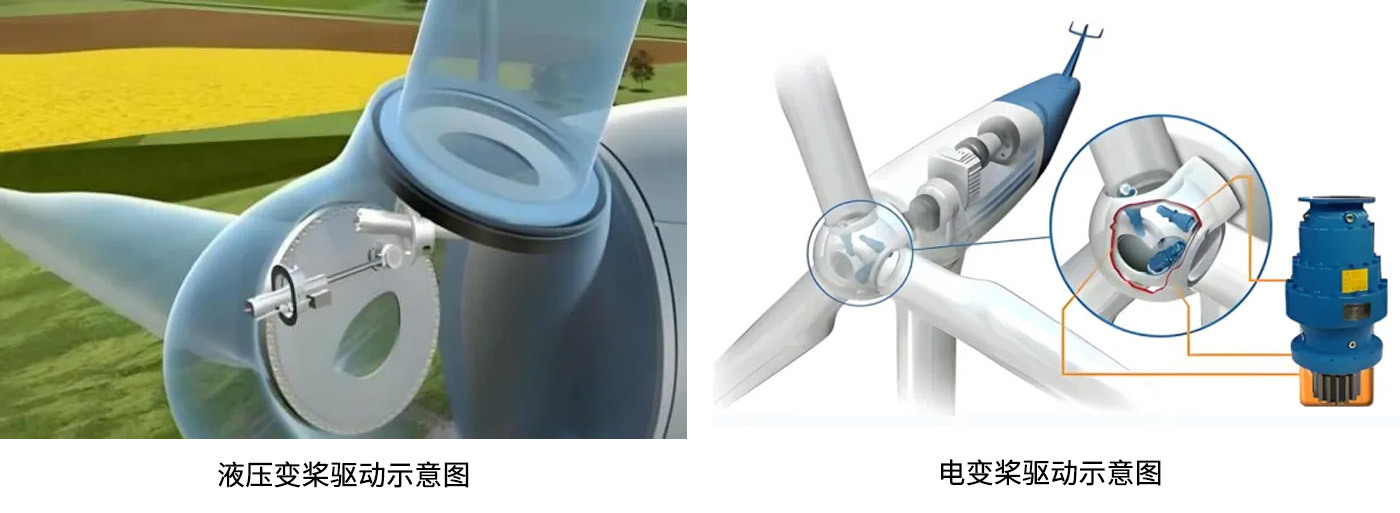

Wind pitch system can be dividedHydraulic and electric pitch systems, The hydraulic pitch system uses the motor to drive the hydraulic pump as the working power, the hydraulic oil as the transmission medium, and the solenoid valve as the control element. The pitch is realized by converting the movement of the cylinder piston rod into the circular motion of the blade.

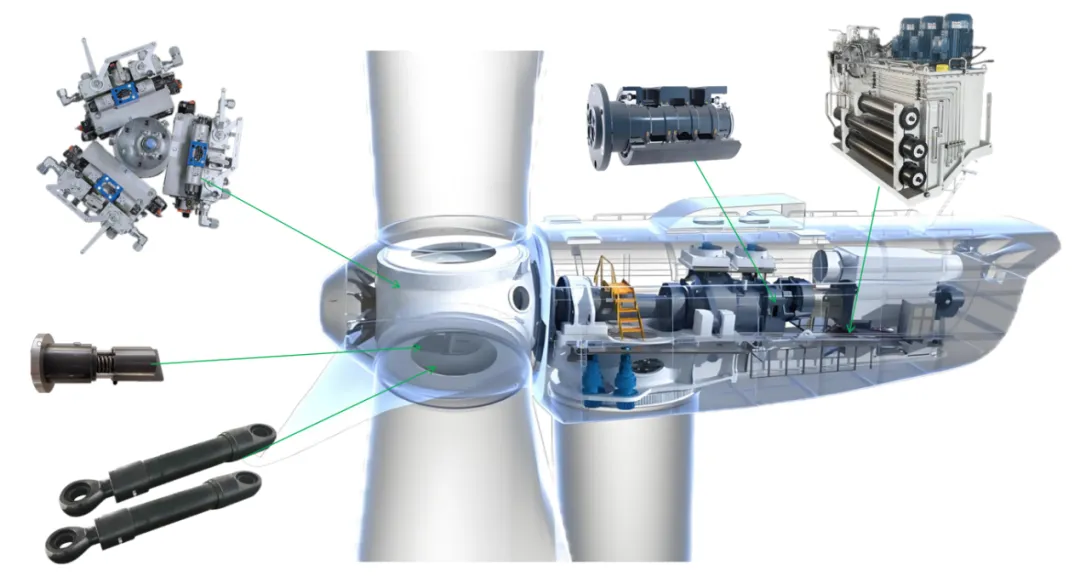

In the hydraulic pitch system, hydraulic pump station, hydraulic slip ring, pitch valve group, proportional valve, accumulator and cylinder are all important components to ensure the normal operation of the system.

The hydraulic pump station provides stable hydraulic power for the entire hydraulic system and is the power source of the system. The hydraulic slip ring is used to connect the hydraulic pump station and the rotating blade part inside the nacelle to ensure that the high-pressure oil can be smoothly transmitted to the pitch valve group and the cylinder. According to the instructions of the control system, the pitch valve group accurately controls the expansion and contraction of the oil cylinder to realize the angle adjustment of the blade. Accumulators play a variety of roles in hydraulic pitch systems, including as an auxiliary power source, maintaining constant system pressure, providing emergency power sources, and absorbing hydraulic shocks. In an emergency, such as a sudden loss of pressure or power failure of the system, the accumulator can quickly release the stored hydraulic oil to ensure that the blade can be safely retracted to a predetermined position. The cylinder is an actuator, which realizes the angle adjustment of the blade according to the instructions of the control system and the adjustment of the pitch valve group.

2. Performance advantages and value advantages of hydraulic pitch

With the continuous development of wind power generation technology, hydraulic pitch system is an important part of wind turbine, and its performance and value advantages are gradually highlighted. Below, the hydraulic pitch system is analyzed in depth from the perspective of performance and value.

01. Performance advantages

High reliability and low failure rate

The hydraulic pitch system adopts mature and stable hydraulic technology, with high reliability and low failure rate. This means that the wind turbine can maintain stable operation for a long time during operation, reduce downtime due to failures, and improve power generation efficiency.

Fast response and precise adjustment

The hydraulic pitch system has faster response speed and higher adjustment accuracy. When the wind speed changes, the hydraulic pitch system can quickly adjust the angle of the wind turbine blades to adapt to different wind speed conditions, thereby ensuring the efficient operation of the wind turbine.

High torque output

The hydraulic pitch system can provide a large torque output, which enables the wind turbine to maintain a stable operating state in the face of a complex wind field environment. At the same time, the high torque output also improves the adaptability and reliability of the wind turbine.

Shock absorption buffer

The existence of hydraulic damping can absorb the impact torque on the blade shaft, and play a good damping effect on the blade and the fan itself.

Simplify maintenance and eliminate the need for tooth surface lubrication

The bearings used in the hydraulic pitch system are simpler, and there is no need to lubricate the gears, reducing the lubrication points of centralized lubrication. In traditional gear systems, tooth surface lubrication is essential to reduce friction and wear between gears. However, the hydraulic pitch system uses hydraulic oil to transmit power, thereby eliminating the need for tooth surface lubrication. This not only simplifies maintenance procedures, but also reduces potential problems due to insufficient or excessive lubrication.

No gear transmission, solve the problem of gear wear

No need for gears, no backlash, fast frequency response, and no gear wear problems: Gear transmissions will gradually fail due to friction and wear during long-term operation and require regular replacement and maintenance. The hydraulic pitch system directly drives the blade to rotate through the hydraulic cylinder without gear transmission, so there is no gear wear problem. This greatly reduces the maintenance cost and failure rate of the system, and improves the reliability and service life of the system.

Emergency feathering, long life and fast response

The accumulator is used as an emergency pitch power to enable emergency feathering in the event of a complete power failure. Long service life and quick response in case of emergency.

02. Value Advantage

Improve power generation efficiency

The hydraulic pitch system enables wind turbines to better capture wind energy and convert it into electrical energy through rapid response and precise adjustment of the angle of the wind turbine blades. This helps to improve the power generation efficiency of the wind turbine and reduce the power generation cost.

Reduce operation and maintenance costs

The high reliability and low failure rate of the hydraulic pitch system reduce the operation and maintenance cost of the wind turbine. At the same time, because the hydraulic pitch system is easy to maintain and repair, it can further reduce the operation and maintenance costs and improve the availability of equipment. In systems with gear drives, when the gears are worn to a certain extent, lifting operations may be required to replace or repair the gears. This not only increases the complexity and cost of maintenance, but also may affect the normal operation of the wind turbine. The hydraulic pitch system does not require gear transmission, so there is no need for such lifting operations, reducing maintenance difficulty and cost.

Improve security

The hydraulic pitch system uses the accumulator as an emergency pitch, which can quickly support the full feathering operation of the hydraulic pitch cylinder in an emergency, thereby improving the safety of the wind turbine. In addition, the stability and reliability of the hydraulic pitch system also helps to reduce safety accidents caused by failures.

Stable and reliable, anti-lightning interference, reduce the risk of downtime

Since the hydraulic pitch system mainly relies on hydraulic oil to transmit power, rather than complex electrical circuits and electrical components, it is not easily affected by lightning, electromagnetic interference, etc. Even in harsh lightning weather conditions, the hydraulic pitch system can maintain good stability and reliability, reducing downtime.

Recommended Reading

Paguld Breaks Ground in Thailand – Key Step in Global Expansion

2025-12-16

2025-12-15